Since the start of the COVID-19 pandemic, every market sector has seen an increased focus on indoor air quality, plant cleanliness, and contamination control. Long before the pandemic began, though, operations in several industries have maintained clean environments as required by their products or services.

Cleanrooms are a common feature in many facilities, including:

- Hospitals and other healthcare facilities

- Laboratories and research facilities

- Food/beverage manufacturing/processing plants

- Semiconductor and solar production plants

- Pharmaceutical and cosmetic production facilities

For decades, operations in these and other areas have relied on dedicated cleanrooms to provide heightened contamination control for part or all of their service or production locations. These rooms employ specialized entry and exit equipment, air handling systems, and personal protective equipment to ensure that particulate and other contaminants are kept to an absolute minimum.

If your facility has a cleanroom, properly cleaning and maintaining the room and its associated equipment is vital to ensuring that you don’t suffer the financial or regulatory burden of a contaminated cleanroom. Here are some tips to help ensure that your cleanroom remains in compliance.

Understand Your Cleanroom’s Requirements

The first step to properly maintaining your cleanroom is educating yourself and your team on the required maintenance and cleaning protocols. Cleanrooms are maintained at various levels of cleanliness and isolation, and each level, or class, of cleanroom has different requirements. For instance, a standard Class 10 cleanroom will have a more relaxed cleaning schedule, airflow and pressure requirements, and maintenance program than a more stringent Class 1 cleanroom.

Understanding how each element of your cleanroom and its systems work together to create a low-contamination site for your operations is vital in understanding how cleaning and maintenance will impact the room’s cleanliness.

Clean From the Top

Cleaning a cleanroom always starts at the ceiling and high walls. As you clean, you’ll knock loose particles and other contaminants that have worked their way into the room, and gravity will pull them down to lower spots. By cleaning from the top down, you’ll minimize the amount of unwanted particles and other matter that remains behind at the end of the cleaning.

Room cleaning should start with the highest surfaces, proceed downward along the walls, and then move to the equipment, countertops, and tables. Then, base cabinets, floor-mounted and freestanding equipment, baseboards or base cove, and floors should be cleaned.

Cleaning in One Direction

When wiping down surfaces in a cleanroom, always work in one direction. Scrubbing back and forth with a cleanroom wipe worsens contamination, as it spreads contaminants across the clean surface and is more likely to knock particles into the air instead of collecting them on the wipe. Vertical surfaces should be wiped downward; horizontal surfaces should be wiped away from the person performing the cleaning.

No Buffing, No Polishing

Floors in a cleanroom are never waxed or buffed. The vigorous polishing action causes particulate matter, excess floor wax or polish, and buffing-pad fibers to stream into the air, potentially overloading filters and leading to a shutdown to return the room to its clean state.

A mixture of deionized water and rubbing alcohol should be used to clean the floors in most cleanrooms.

Keep Cleanroom-Specific Cleaning Supplies

Cleanroom cleaning supplies should be kept separate from general cleaning supplies, which should never be allowed into the cleanroom. Many cleaning solutions and tools used in a cleanroom are already specialized for that environment, and the supplies used in the rest of the facility are not up to the standards required for cleanroom maintenance.

Additionally, bringing in cleaning supplies from other parts of the facility will almost certainly introduce contaminants into your clean environment, leading to a dreaded shutdown and decontamination.

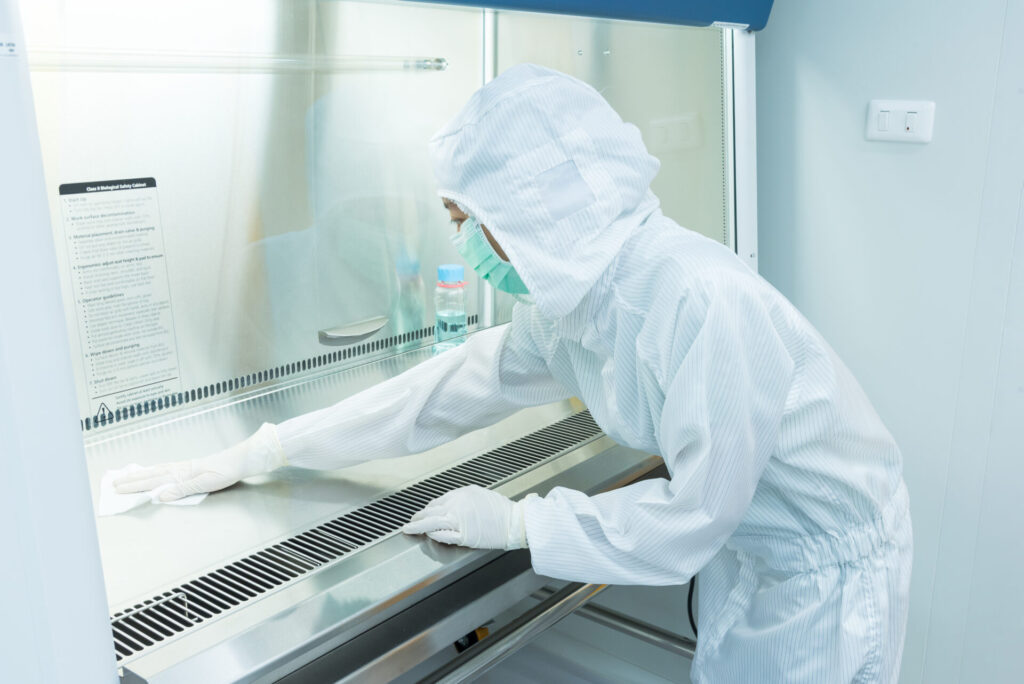

Personal Protection Is Cleanroom Protection

How your team utilizes their personal protective equipment (PPE) is fundamental to keeping your cleanroom contaminant-free. Depending on the class of cleanroom, workers entering and exiting the room will be required to don varying levels of PPE, including full-body “bunny suits,” head covers, face masks, eye coverings, gloves, and booties.

Maintaining the integrity of each worker’s PPE is vital. Workers should wash their hands thoroughly before suiting up, as dirt from the hands will be transferred to the PPE as it’s put on. The dressing room should be kept as clean as possible, and PPE should be kept in its protective wrapping until the last possible second before an employee puts it on.

Employees should remove their dirty PPE from the top down when exiting the cleanroom, reserving the gloves for last. Once everything else has been removed, the gloves should be removed by turning them inside out and disposing immediately.

Does Your Facility Require a Cleanroom? Let JLJ and Associates Help!

JLJ and Associates have years of experience building cleanrooms and other specialized interior spaces for commercial, healthcare, or other facilities. Give us a call today to find out how we can develop a cleanroom solution that works for you! 770-961-7600

Related Articles: